.

Home >

Research & Development

Home >

Research & Development

Research & Development

Concrete Solutions

OMC Collareda can provide engineering services at different levels depending on the Customer requirements.

Basic Engineering

Complete sets of assembly and installation drawings, certificates and manuals to allow safe and efficient assembly and start up of the equipment included in the supply.

Detailed Engineering

It includes on site visits of OMC Collareda technicians to discuss and agree the installation of the equipment and accessories included in the supply. Complete sets of assembly and detailed installation drawings, manufacturing and assembly drawings for piping, specifications of accessories, equipment and field instrumentation and relevant lay out. 2D or 3D engineering documentation can be provided. Drawings for civil work realization. Electric and instrumentation engineering. Detailed flow diagram. Certificates and manuals for all equipment supplied, according to CE directives (assembly and use, start-up and maintenance manuals). OMC Collareda can offer a complete engineering service for the supply of a “turnkey plant”, assembly start up and commissioning included.

Request

Filtering and Thickening system.

Needs

Innovative, brand new design.

Reduction of wire maintenance and replacement activities.

Management of a high quantity of suspended solids, draining water to which the ppm load is reduced considerably.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

3 MONTHS

Results

Suitable clarification level of residual water, removal of COD higher than what estimated during the planning phase and remarkable removal of TSS (~99%)

Request

Resin filter to remove COD.

Needs

Innovative, brand new design.

Reduction of maintenance and replacement interventions of resins.

Reduction of COD (Chemical Oxygen Demand) to legal levels.

Construction in stainless steel.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

11 MONTHS

Results

A suitable elimination level of COD is reached, in compliance with laws, through simple equipment and reduced maintenance costs.

Request

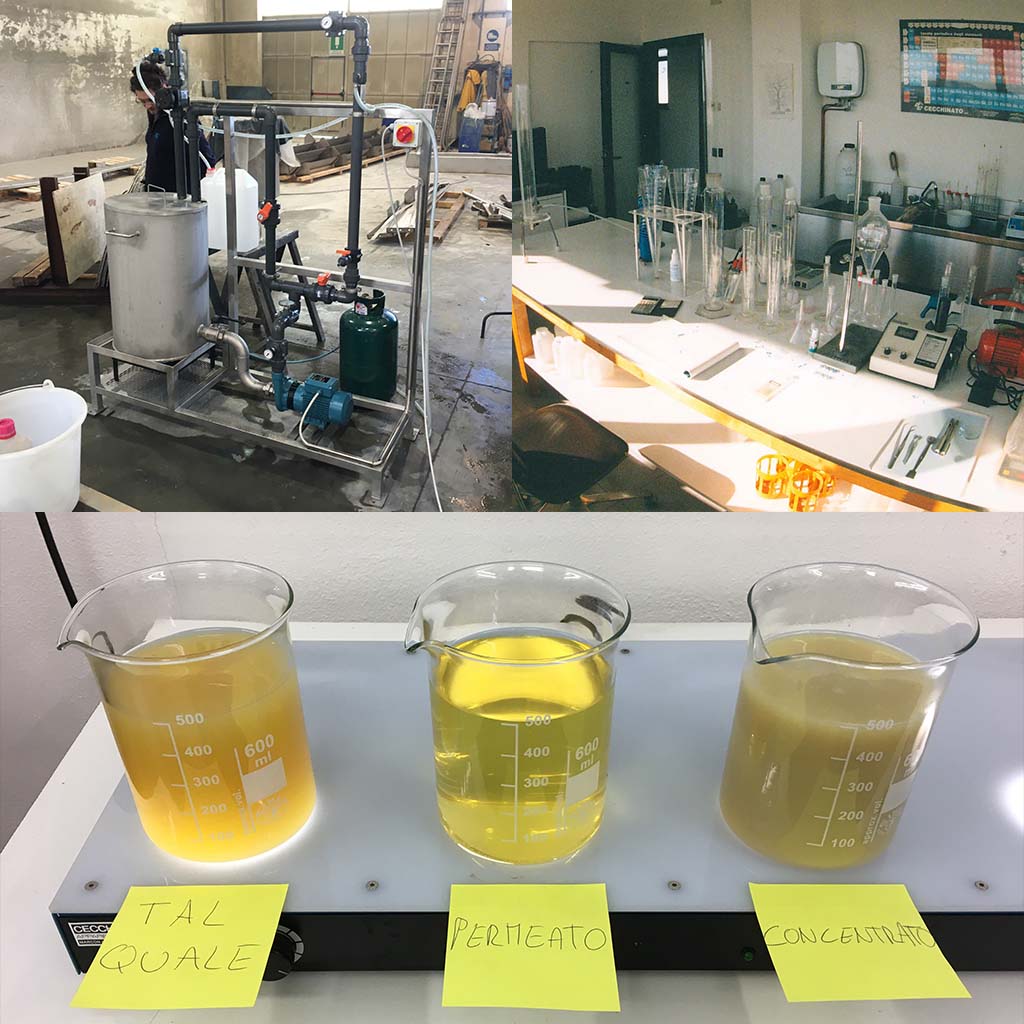

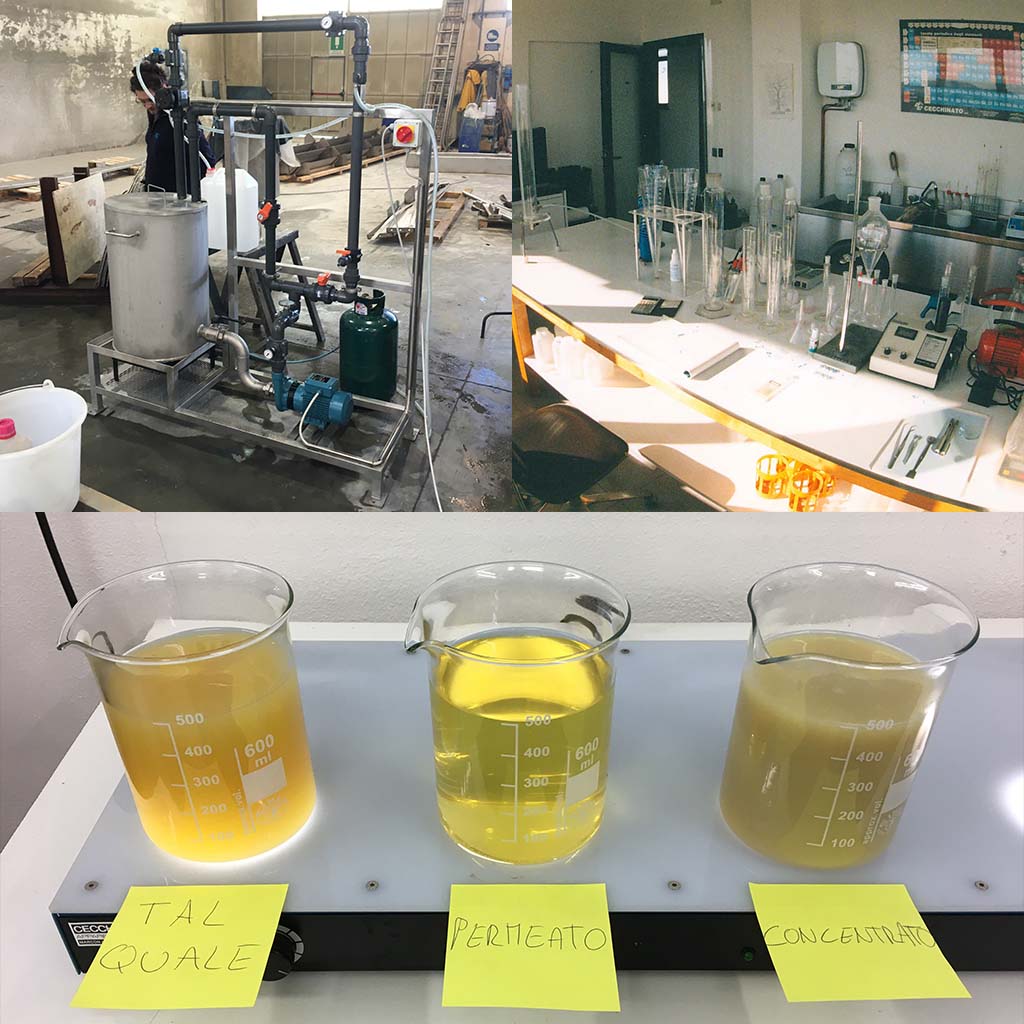

Tubular membrane filter.

Needs

Innovative, brand new design.

Reduction of maintenance and replacement interventions of membranes.

Reduction of COD (Chemical Oxygen Demand) to legal levels.

Reduction of TSS.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

3 MONTHS

Results

Suitable clarification level of residual water, removal of COD higher than what estimated during the planning phase and remarkable removal of TSS (~99%)

Concrete Solutions

OMC Collareda can provide engineering services at different levels depending on the Customer requirements.

Basic Engineering

Complete sets of assembly and installation drawings, certificates and manuals to allow safe and efficient assembly and start up of the equipment included in the supply.

Detailed Engineering

It includes on site visits of OMC Collareda technicians to discuss and agree the installation of the equipment and accessories included in the supply. Complete sets of assembly and detailed installation drawings, manufacturing and assembly drawings for piping, specifications of accessories, equipment and field instrumentation and relevant lay out. 2D or 3D engineering documentation can be provided. Drawings for civil work realization. Electric and instrumentation engineering. Detailed flow diagram. Certificates and manuals for all equipment supplied, according to CE directives (assembly and use, start-up and maintenance manuals). OMC Collareda can offer a complete engineering service for the supply of a “turnkey plant”, assembly start up and commissioning included.

Contact US

Request

Filtering and Thickening system.

Needs

Innovative, brand new design.

Reduction of wire maintenance and replacement activities.

Management of a high quantity of suspended solids, draining water to which the ppm load is reduced considerably.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

3 MONTHS

Results

Suitable clarification level of residual water, removal of COD higher than what estimated during the planning phase and remarkable removal of TSS (~99%)

Request

Resin filter to remove COD.

Needs

Innovative, brand new design.

Reduction of maintenance and replacement interventions of resins.

Reduction of COD (Chemical Oxygen Demand) to legal levels.

Construction in stainless steel.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

11 MONTHS

Results

A suitable elimination level of COD is reached, in compliance with laws, through simple equipment and reduced maintenance costs.

Request

Tubular membrane filter.

Needs

Innovative, brand new design.

Reduction of maintenance and replacement interventions of membranes.

Reduction of COD (Chemical Oxygen Demand) to legal levels.

Reduction of TSS.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

3 MONTHS

Results

Suitable clarification level of residual water, removal of COD higher than what estimated during the planning phase and remarkable removal of TSS (~99%)

Concrete Solutions

OMC Collareda can provide engineering services at different levels depending on the Customer requirements.

Basic Engineering

Complete sets of assembly and installation drawings, certificates and manuals to allow safe and efficient assembly and start up of the equipment included in the supply.

Detailed Engineering

It includes on site visits of OMC Collareda technicians to discuss and agree the installation of the equipment and accessories included in the supply. Complete sets of assembly and detailed installation drawings, manufacturing and assembly drawings for piping, specifications of accessories, equipment and field instrumentation and relevant lay out. 2D or 3D engineering documentation can be provided. Drawings for civil work realization. Electric and instrumentation engineering. Detailed flow diagram. Certificates and manuals for all equipment supplied, according to CE directives (assembly and use, start-up and maintenance manuals). OMC Collareda can offer a complete engineering service for the supply of a “turnkey plant”, assembly start up and commissioning included.

Request

Filtering and Thickening system.

Needs

Innovative, brand new design.

Reduction of wire maintenance and replacement activities.

Management of a high quantity of suspended solids, draining water to which the ppm load is reduced considerably.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

3 MONTHS

Results

Suitable clarification level of residual water, removal of COD higher than what estimated during the planning phase and remarkable removal of TSS (~99%)

Request

Resin filter to remove COD.

Needs

Innovative, brand new design.

Reduction of maintenance and replacement interventions of resins.

Reduction of COD (Chemical Oxygen Demand) to legal levels.

Construction in stainless steel.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

11 MONTHS

Results

A suitable elimination level of COD is reached, in compliance with laws, through simple equipment and reduced maintenance costs.

Request

Tubular membrane filter.

Needs

Innovative, brand new design.

Reduction of maintenance and replacement interventions of membranes.

Reduction of COD (Chemical Oxygen Demand) to legal levels.

Reduction of TSS.

Planning

Design study phase

Preparation of the first drawings

Procurement of materials

Construction of prototype in the workshop

Test and various checks

3 MONTHS

Results

Suitable clarification level of residual water, removal of COD higher than what estimated during the planning phase and remarkable removal of TSS (~99%)

Technical Office

A team of engineers and technicians is able to give to the Customer the assistance already during the first approach, giving them the necessary support during the trials, the installation and the start up, thanks to their experience.

Technical Office

A team of engineers and technicians is able to give to the Customer the assistance already during the first approach, giving them the necessary support during the trials, the installation and the start up, thanks to their experience.

R&D Laboratory

OMC is equipped with the most advanced instruments to allow to run tests on water samples received by the Customer, on samples collected from pilot units while trials at Customer’s and to simulate the operating processes. Tests help to identify the suitable process to be applied for the specific application and to determine the performances of the equipment to be installed.

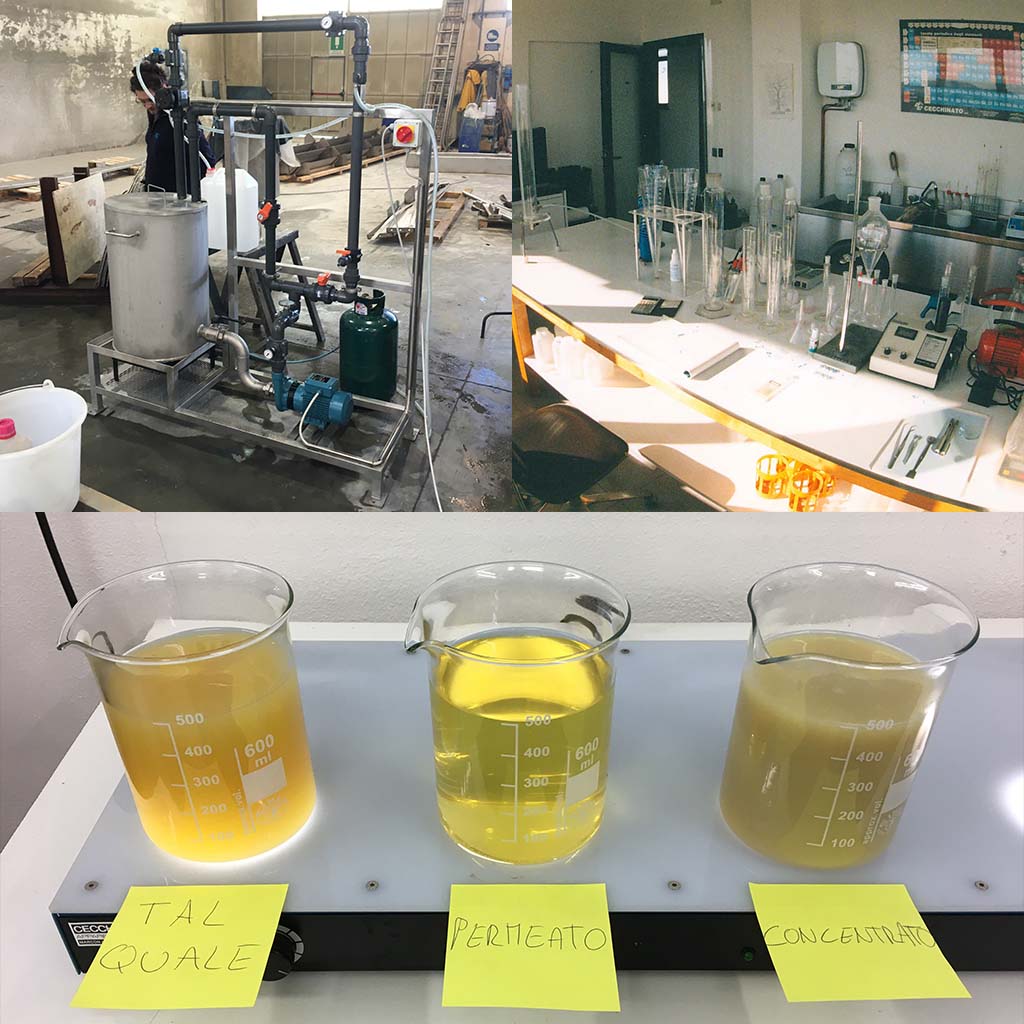

Pilot Unit Trials

OMC Collareda Research and Development Laboratory owns pilot units of each equipment included in its production program.

They are available for trials at Customer’s site.

Their design, working and performance correspond exactly to the industrial size plants that will be installed. OMC give to the Customer the necessary support during the trials, the installation and the start up.

Contact US

R&D Laboratory

OMC is equipped with the most advanced instruments to allow to run tests on water samples received by the Customer, on samples collected from pilot units while trials at Customer’s and to simulate the operating processes. Tests help to identify the suitable process to be applied for the specific application and to determine the performances of the equipment to be installed.

Pilot Unit Trials

OMC Collareda Research and Development Laboratory owns pilot units of each equipment included in its production program.

They are available for trials at Customer’s site.

Their design, working and performance correspond exactly to the industrial size plants that will be installed. OMC give to the Customer the necessary support during the trials, the installation and the start up.

R&D Laboratory

OMC is equipped with the most advanced instruments to allow to run tests on water samples received by the Customer, on samples collected from pilot units while trials at Customer’s and to simulate the operating processes. Tests help to identify the suitable process to be applied for the specific application and to determine the performances of the equipment to be installed.

Pilot Unit Trials

OMC Collareda Research and Development Laboratory owns pilot units of each equipment included in its production program.

They are available for trials at Customer’s site.

Their design, working and performance correspond exactly to the industrial size plants that will be installed. OMC give to the Customer the necessary support during the trials, the installation and the start up.